Imagine this: you’re in the middle of a critical production run, everything’s humming along… until your CNC machine’s control system freezes. The parts are halfway done, the clock is ticking, and your team is scrambling to find a workaround. The problem? Your control unit is old, outdated, and struggling to keep up with today’s demands.

This is exactly where a modern CNC control retrofit can be a game-changer. Instead of replacing your entire machine—a cost that can feel like buying a new house—you can breathe new life into your existing equipment with updated controls. It’s like giving your trusty old car a high-performance engine and a digital dashboard without losing the comfort of the driver’s seat you know so well.

Let’s dive into the real-world benefits that make a retrofit worth considering.

1. Better Performance Without Buying New Equipment

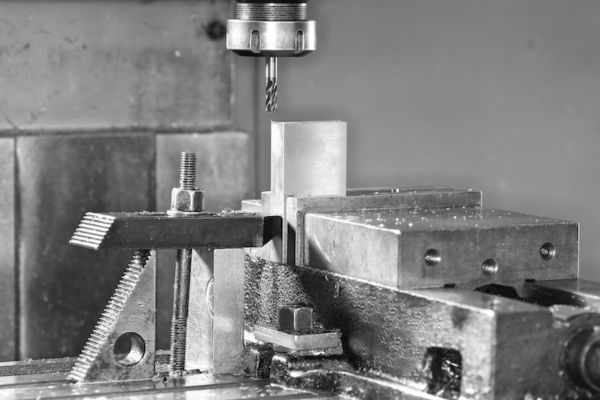

The first and most obvious benefit: performance. A control retrofit transforms an older CNC into a more precise, faster, and capable machine. It’s not just about adding a shiny new screen—it’s about upgrading the brain of the system.

Modern controls process complex toolpaths faster, handle more advanced programming, and respond more efficiently to changes. You get the production capabilities of a new machine, but you keep the sturdy frame and mechanics that are already proven in your shop.

2. Reduced Downtime and Maintenance Costs

Outdated control systems are notorious for downtime. Replacement parts can be hard to find, service technicians familiar with old software are rare, and even a small glitch can stall production for hours or days.

With a modern retrofit, you’re installing technology that’s actively supported by the manufacturer. This means easy access to replacement parts, software updates, and a wider pool of technicians who can troubleshoot issues quickly. Less downtime means more parts out the door—and more revenue in your pocket.

3. Access to Advanced Features and Automation

Think about how much technology has evolved in the last 10 years—smartphones, streaming, AI assistants. CNC controls have advanced just as dramatically. A retrofit can give you features like:

High-speed machining algorithms for smoother, faster cuts

Real-time tool monitoring to prevent breakage

Remote monitoring so you can check production from anywhere

Simplified user interfaces that new operators can learn quickly

This isn’t just about convenience—it’s about staying competitive in a market where faster turnaround and higher precision are becoming the norm.

4. Improved Energy Efficiency

Old control systems tend to run inefficiently, consuming more power than necessary. Modern controls are built with energy-saving features and smarter power management. While the energy savings alone might not justify the entire upgrade, they do add up over time—especially if you run multiple machines around the clock.

5. Extending the Life of Your Machine

If your machine’s mechanical structure is still solid, a retrofit can easily extend its useful life by another decade or more. That means you keep producing with a familiar machine—without the learning curve or retooling costs that often come with brand-new equipment.

It’s a bit like renovating a house instead of building a new one: you keep the strong foundation but modernize what matters most.

6. Boosting Operator Confidence and Productivity

Operators love a control interface that’s intuitive, responsive, and reliable. When the controls are easier to use and less prone to errors, operators can focus on production rather than babysitting the machine. That morale boost often translates directly into better output and fewer mistakes.

Final Thoughts

A CNC control retrofit isn’t just a technical upgrade—it’s a strategic business move. It gives you the speed, accuracy, and reliability of a modern machine without the massive capital investment of buying new. In today’s fast-paced manufacturing world, that edge can make all the difference between keeping up and falling behind.

If your CNC machine is mechanically sound but held back by outdated controls, it might be time to stop patching the old system and start planning for a retrofit. After all, your best machine might just be the one you already own—upgraded for the future.

Write a comment ...