In the world of precision machining, accuracy isn't just a goal—it’s a necessity. Whether you're running a small job shop or a large-scale manufacturing facility, maintaining your CNC machines in peak condition is essential for delivering top-quality results. But when something feels “off,” how do you pinpoint the root of the problem? That’s where diagnostics come in. And in today's industry, there’s a quiet debate happening behind the scenes: Ballbar testing vs traditional diagnostic methods. Which one truly gives you the edge?

Let’s unpack both approaches and see which one is more effective in keeping your machines humming.

Understanding Traditional Diagnostics

Before digital tools became the norm, diagnosing CNC issues was a craft in itself. Technicians relied on visual inspections, manual tests, operator feedback, and a wealth of experience to track down problems. They would check for things like backlash, unusual sounds, worn parts, or inconsistent finishes.

While this method is still widely used, it often involves a bit of educated guesswork. It’s like trying to diagnose a car problem just by listening to the engine rattle—sometimes it works, but sometimes you miss the deeper issue.

Traditional diagnostics can be time-consuming and might not catch subtle issues until they become costly problems. But on the flip side, seasoned technicians develop a sixth sense about machines, and that intuition can be invaluable—especially for spotting mechanical wear or process-based inconsistencies.

What is Ballbar Testing?

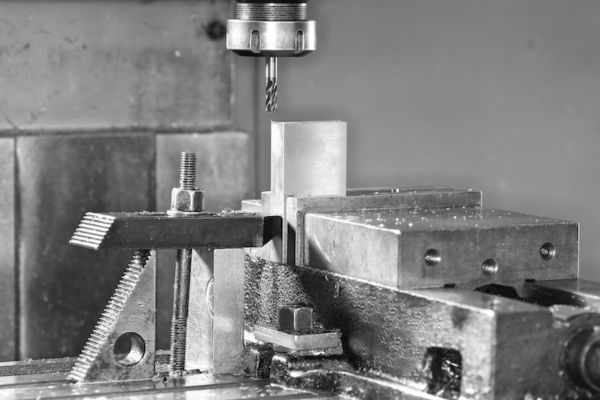

Ballbar testing, on the other hand, is more of a precision-driven, data-backed approach. It uses a telescopic ballbar device to measure the deviation of a CNC machine's circular movement. This test records the actual path of the machine as it attempts to trace a perfect circle, then compares it to the ideal path.

The beauty of this method lies in its simplicity and depth. Within just a few minutes, a ballbar test can expose alignment errors, backlash, squareness problems, servo mismatches, and even machine geometry issues. It's like giving your machine an MRI scan—non-invasive, highly accurate, and incredibly telling.

Speed vs Insight: The Real Tradeoff

If you’re looking for a quick answer to which is more effective—ballbar testing takes the lead in precision diagnostics, hands down. It delivers quantifiable, repeatable data that doesn’t rely on interpretation alone. You can benchmark your machine, track degradation over time, and even predict when maintenance will be needed before failure happens.

That said, traditional diagnostics shouldn’t be completely dismissed. There are scenarios where human insight catches what data cannot—subtle noises, operator-induced issues, or context-sensitive problems that a ballbar simply won’t detect.

For example, a ballbar test might show everything is fine geometrically, but if a spindle bearing is about to go, only a trained ear or a vibration analysis might pick that up. So really, it’s not an “either-or” situation—it’s more about complementing the data with real-world experience.

Cost and Accessibility

Let’s be real—ballbar systems are an investment. The equipment, software, and training aren’t cheap. But the return on investment can be significant, especially in environments where uptime, accuracy, and consistency are non-negotiable.

Traditional diagnostics, meanwhile, require little to no upfront cost—just time and know-how. This makes it more accessible, especially for smaller shops that can’t justify expensive tech but still need effective troubleshooting.

Still, as CNC technology becomes more advanced, the margin for error shrinks. The cost of not catching an issue in time can be far greater than the cost of preventative ballbar testing.

So, Which One’s More Effective?

Effectiveness depends on what you're solving for. If you need fast, repeatable, quantifiable insights into machine accuracy, ballbar testing is your best friend. It’s especially useful for preventive maintenance programs and quality control routines.

But if you're diagnosing strange noises, unusual tool wear, or operator complaints, traditional methods still have a seat at the table. The best shops combine both—using ballbar testing for accuracy benchmarking and traditional diagnostics for broader, experience-based evaluations.

Final Thoughts

In today’s competitive machining world, knowing how your CNC machine is performing—and why—can make or break your production line. Ballbar testing gives you the hard data; traditional diagnostics provide the seasoned judgment. Together, they form a powerful maintenance strategy that blends technology with hands-on expertise.

So instead of choosing one over the other, maybe the real answer is this: the most effective diagnostics come from balance—where digital precision meets human intuition.

Write a comment ...