In manufacturing, time truly is money. A single unexpected halt in production due to a malfunctioning CNC machine can send schedules off course, increase costs, and frustrate clients. That’s why reliable CNC machine tool services aren’t just a nice-to-have—they’re essential to keeping operations smooth and productivity high.

Take it from a shop floor manager I spoke with recently—let’s call him Raj. His team runs a tight schedule, producing custom components for the automotive industry. A minor spindle issue once brought their most critical machine to a standstill. But thanks to a responsive CNC service team, what could’ve been a multi-day delay was resolved within hours. That kind of support doesn’t just fix machines; it saves relationships and reputations.

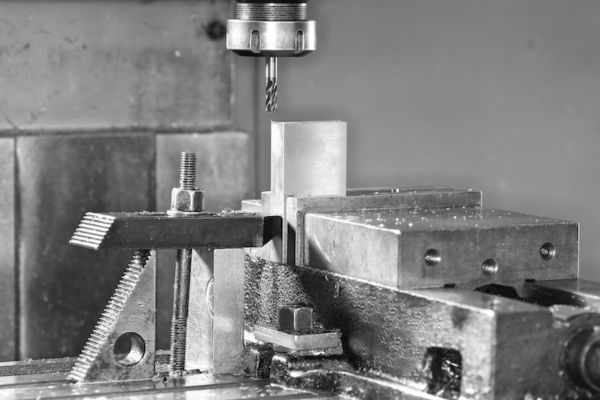

The right service partner does more than just repairs. They proactively monitor performance, fine-tune alignments, perform precision calibrations, and even retrofit older machines to meet today’s standards. It’s about keeping your tools not just running, but running at their best.

And let’s not forget the human element. Skilled technicians who understand both the hardware and the pressures of production timelines can make a huge difference. They’re not just wrench-turners—they’re problem-solvers, advisors, and occasionally, heroes in steel-toed boots.

In the end, CNC machine tool services are like good insurance—when they’re reliable, you hardly notice them. But when you need them, you’ll be thankful they’re just a call away. Consistent maintenance and expert support can mean the difference between scrambling to catch up and cruising ahead of deadlines.

Your machines work hard. Make sure they’re backed by a team that works just as hard.

Write a comment ...