A few years ago, I walked into a small machine shop tucked behind a row of hardware stores. It was the kind of place where every square foot mattered, the coffee pot never got cold, and the machines—well, they had stories. But what caught my eye wasn’t just the vintage iron; it was the operator struggling with a control system that looked like it came from the Cold War era.

“It gets the job done,” he said, half-proud, half-exhausted. “But she’s temperamental.”

Sound familiar?

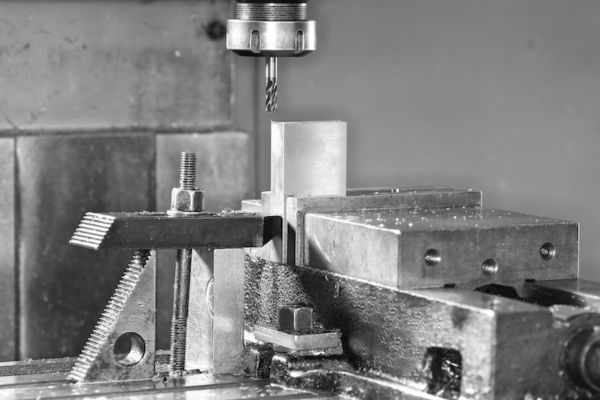

If you run or work in a small or medium-sized workshop, chances are you’ve got at least one CNC machine that’s still running on outdated controls. It may still cut metal, but let’s be honest—it’s clunky, inefficient, and prone to surprise tantrums.

Enter CNC control retrofits—an upgrade that doesn’t mean replacing your entire machine but rather giving its brain a much-needed boost. And for smaller shops, the benefits aren’t just technical—they're transformative.

1. Boost Productivity Without Breaking the Bank

Full machine replacements are expensive. For many small and medium-sized shops, they’re just not feasible. A CNC control retrofit offers a sweet middle ground—modern performance at a fraction of the cost.

By upgrading the control system, you can dramatically reduce setup times, minimize program errors, and streamline workflows. In one case, a retrofit I was involved with shaved 40% off the average job time just by eliminating slow manual inputs and outdated G-code quirks.

Think of it like putting a new engine in a classic car. The body’s still solid—it just needs modern brains to keep up with today’s pace.

2. Fewer Breakdowns, More Reliability

Old control systems are like old radios—one loose wire, and suddenly you’ve got static. Many legacy controls rely on outdated components that are no longer manufactured, and when something fails, finding replacements can feel like a scavenger hunt.

Retrofits replace that fragile legacy tech with reliable, supported, and often modular components. The result? Fewer unplanned stoppages, less time on the phone hunting down obsolete parts, and more time doing what matters—cutting parts and meeting deadlines.

3. Modern Interfaces Are Just... Easier

Let’s be real—some older CNC controls require a degree in patience and a minor in Morse code.

Modern retrofitted controls offer intuitive interfaces, often with touchscreens, better visualization tools, and user-friendly navigation. For operators, especially new ones, this makes a world of difference. The learning curve flattens, and training becomes less of a headache.

I once trained a young machinist on a retrofitted mill with a conversational interface, and by the end of the day, he was running jobs solo. That would’ve taken weeks on the original controller.

4. Extend the Life of Your Machines

Many small shops are running solid iron—machines built like tanks but saddled with outdated electronics. A retrofit breathes new life into those machines, turning them into high-performing assets again.

It’s a sustainable, smart investment. You’re protecting the value of your existing equipment while pushing its capabilities closer to what modern jobs demand. And in today’s lean manufacturing environment, squeezing more life out of what you already own is a competitive edge.

5. Access to Modern Features

Today’s CNC controls offer features that just weren’t available on older systems:

Real-time diagnostics

Advanced toolpath optimization

Adaptive feeds and speeds

USB or Ethernet connectivity for file transfers

Remote monitoring or even mobile alerts

These aren’t just “nice-to-haves.” They save time, reduce scrap, and help small shops compete with larger operations.

6. Better Integration With CAD/CAM Software

If your current workflow involves awkward file conversions or manually inputting code line by line, you're not just wasting time—you're inviting errors.

Modern CNC control retrofits typically play well with today's CAD/CAM software. That means smoother transitions from design to production, fewer surprises on the shop floor, and faster turnaround times for customers.

7. Increased Job Flexibility and Capability

Ever turned down a job because your machine just couldn’t handle the complexity? With updated controls, you unlock the potential to:

Run more intricate toolpaths

Handle tighter tolerances

Take on more complex geometries

This isn’t just a technical upgrade—it’s a business opportunity. Suddenly, your shop can say "yes" to the kind of jobs that once seemed out of reach.

Final Thoughts

For small and medium workshops, the decision to retrofit a CNC machine can feel like a leap. There’s the learning curve, the downtime, the upfront cost. But time and again, I’ve seen that leap pay off—not just in smoother operations, but in the pride that comes from running a shop that’s lean, modern, and ready for the next challenge.

A CNC control retrofit doesn’t just upgrade your machine—it upgrades your entire workflow, your team’s confidence, and your capacity to grow.

And maybe, just maybe, you’ll finally retire that old controller with the sticky buttons and temperamental screen.

Trust me, your shop (and your sanity) will thank you.

Write a comment ...